- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

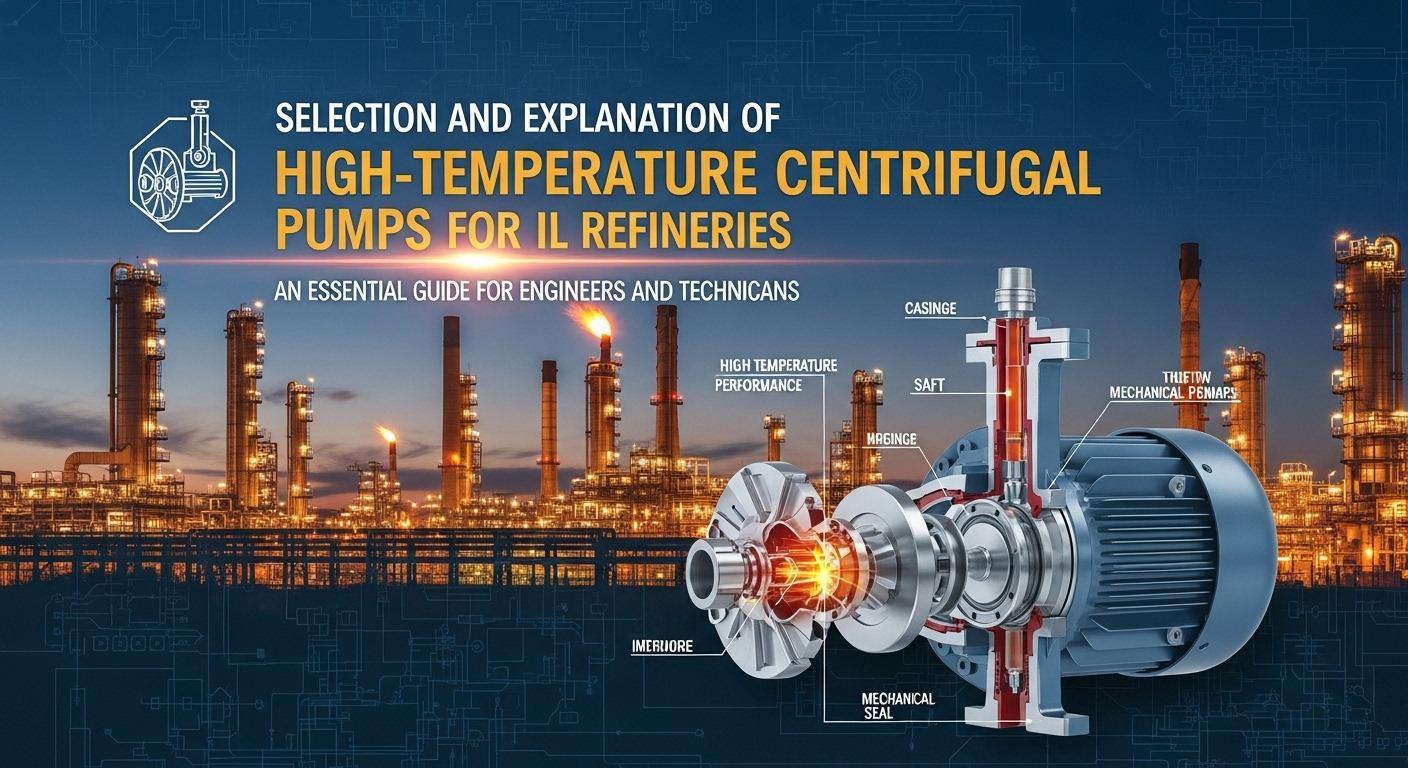

In the rumbling production workshops of oil refineries, from the transportation of 480℃ oil and gas in catalytic cracking units to the transfer of 380℃ residual oil in vacuum distillation systems, there is always a set of equipment operating continuously under high-temperature conditions — it is the high-temperature centrifugal pump for oil refineries. As the core transportation hub for high-temperature media in the refining and chemical process, it connects the key links of "heating - reaction - separation". This article will start from the core characteristics of high-temperature centrifugal pumps in oil refineries, compare their essential differences with ordinary pumps, sort out the key dimensions of scientific selection, and further deeply analyze why the Teffiko

In the rumbling production workshops of oil refineries, from the transportation of 480℃ oil and gas in catalytic cracking units to the transfer of 380℃ residual oil in vacuum distillation systems, there is always a set of equipment operating continuously under high-temperature conditions — it is the high-temperature centrifugal pump for oil refineries. As the core transportation hub for high-temperature media in the refining and chemical process, it connects the key links of "heating - reaction - separation". This article will start from the core characteristics of high-temperature centrifugal pumps in oil refineries, compare their essential differences with ordinary pumps, sort out the key dimensions of scientific selection, and further deeply analyze why the Teffiko